Diffusion Sapphire factory

Diffusion Blue Sapphire Factory – manufacturer of the only treated sapphire that is close to nature.

The word diffusion scares people away, especially those that were born in the earlier ’60s. But for the post-millennial, the treated sapphires are absolutely normal. The earth’s crust is depleting its sources of natural raw sapphires, especially those that come clean and for the long run, we believe treated sapphires will definitely create its market, just like Lightbox from Debeers has set the jewelry industry on fire by launching Created Diamonds.

Navneet Gems and Minerals is a wholesale diffusion blue sapphire factory located in the heart of Bangkok, at Silom Road. Our 25+ years of absolutely hard work and patience have led us to diversify into as many as 140 types of stones. Sapphire and Rubies are very important for our gemstone cutting factory in Bangkok.

So what is the difference between a diffusion blue sapphire and other treatments?

Most people already know the difference between heated and unheated sapphire but it’s very important to know the different types of treated sapphire in the gem industry. Diffusion is considered the best treatment in sapphires because the stone is actually a natural stone, with its inclusions and internal flaws being unchanged, only a blue color is “diffused” into the natural-looking clear sapphire. As mother earth gets tired, there is still a lot of sapphires to be mined but most of them come out as poor color, (light) and not much color.

These are the stones that are used to treat Lattice diffusion. When diffusion sapphire from Thailand is compared with other treatments like glass filling, it’s much more sustainable and maintains its market because glass filling has color, clarity and everything else enhanced. The inclusions are turned into the base color and it disappears. Critics have mentioned glass filling treatment as not sustainable (the glass starts to come out) and not real ruby or sapphire because of too much filling.

One of the first photos GIA got was from our friend Mr. Terry Coldham, Australian Gemologist and well known reputed Opal and Sapphire seller, as below:

A photo with Mr. Coldman is here when we met each other during a conversation about Diffusion sapphires from Australia at the Tucson Gem Show 2017: https://www.instagram.com/p/BtKsoe0HLQy

A primitive approach (Diffusion sapphire process):

The easiest method of differentiating diffusion sapphire is by taking a torch, lighting it on, putting a tissue on top of the light (so the torch is facing your chin) and if one layer of tissue is leaking too much light, put some more layers until only 35-40% of the light is coming out. Now put the stone on the tissue with light from underneath, you will see layers of diffusion especially concentrations of color on the edges. This is a clear sign that this sapphire has been treated with lattice diffusion. However, please note this is a very easy quick check, but it is not a concrete answer, the 100% way is to have it tested at a lab.

Sourced directly from our Gemstone cutting diffusion sapphire factory in Bangkok, Thailand

It’s very important in this tough competitive business, to find a source that’s reliable, consistent, and most important priced right. The jewelry business is much tougher than it was 10 years ago, you have to not only beat the competition but also make sure you are 3 steps ahead. One of those steps is your source of colored gemstones.

Navneet Gems’ customers worldwide accept that since they have been in touch with our company, it’s not only become better for them, but they have excess too much more information than they were earlier. Asian manufacturers of gemstones tend to keep a lot of secrets for themselves; the treatment, factory, capacity, sales volume – you’ll never get these equations sorted with them. With us, we give you as much information as we can to educate you to be a good buyer.

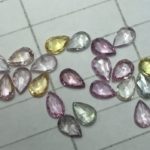

Our treated sapphires are treated with our Thai partners, the diffusion of the sapphire takes place in Bangkok, near Silom Road, and in Chantaburi in laboratories. Our cutting factory is located near the center, just a few kilometers away from Silom – our 4 skilled cutters of sapphire cut diffusion sapphires from the smallest 4×3 up to 10×8’s in quantities of 100,200 and 500 carats at a point. It does happen that we take orders and cut on specific sizes, depending on the market condition.

If you are looking for a one-time $1,000 purchase, we are not the company for you. However, if you need quantities of diffusion-treated sapphire every month, our company is the right source for it. We are the direct source of rough from the mines in Madagascar and Ceylon and Kanchanaburi– with the help of our Thai partners, we treat to perfection, our cutters leave no polishing marks, pits, holes in the finest of the quality. We produce however every quality from A grade (inclusion base) up to AAA, that’s how the rough comes out from the earth. This is the Diffusion sapphire process and the diffusion sapphire price can depend on the finishing of the polish and quality of diffusion treatment.

Here you can check, How To Detect Diffusion Treatment In Sapphires In 30 Seconds

Email us at info@navneetgems.com or Whatsapp / Viber at +66985498500 for an instant reply. You can also add him on skype: Navneet.agarwal1