Semi Precious Gemstone Manufacturing

Rough stones to ready material process are called manufacturing process. Thailand, India, and China are well-known hubs for gemstone manufacturing. India is famous for handmade gemstones and china is famous for machine-made stones. When it comes to custom designs then no one can beat India and Thailand. Thailand’s market is known for precious gems and India’s market is popular for semi-precious gems. When we talk about a particular city in India then Jaipur comes first (more than 85% manufacturing), the rest are in other parts of India.

View this post on Instagram

The gemstone manufacturing process – Gemstone supply is a long chain that starts from rough mining holders then follows rough dealers, raw material exporters, local rough dealers than manufacturers, and so on. Let’s take an example of Tanzanite rough which is mined in Tanzania (the only source of rough). They sell to local rough dealers in Tanzania then the dealers contact importers (rough buyers) from other countries and they sell them. Further local rough dealers sell to local manufacturers. Local manufacturers ready the stones and release them in the market to sell. So basically when you will study this scenario then you will get to know that it is coming through more than 15 to 20 hands and every person (seller) is taking their margin. Here arises a question?

View this post on Instagram

How do we stand from other gemstone manufacturers?

Well, we have direct contact from mining holders and our team regularly visits there and buys big rough in big quantities. Big quantities rough come in our own factory for cutting and polishing process. This way we skip many hands and this clearly reflected in our prices and grade of stones. We have written an article about the gemstones manufacturing process which you can study here – A complete guide for the wholesale gemstones manufacturing process.

Many people think about semi-precious gemstone manufacturing and all know the pros, only a few only the cons. We have been a consistent manufacturer. We have seen many small ventures start their factory and disappear in just a few years.

Here are few key points that make us better wholesale gemstones suppliers than other gemstone manufacturers?

- We have an online catalog that makes for a concise repertoire of our collection. We can replenish products according to your design and your will.

- We have done regular updates on post arrivals and special offers on our social media channels.

- You can now go through our complete collection and place a direct order to us through the app!

- Last but not least, you can directly communicate with our marketing manager head Mr. Navneet Agarwal for any gemstones related queries.

Here, you can check out our Introduction to Navneet Gems – Corporate video

Here are some reasons why most of the manufacturers fail and how we overcome all such problems?

1. Inconsistency in labors – Labour market is not officially running basically there is no tenure between labor and factory. They are working on faith and their own choice. Most of the small manufacturers fail when their laborers suddenly leave them without any prior notice. Reasons may be lack of facility, low pay scale, and poor environment of work.

How do we survive in this scenario? – We provide the best possible facility and pay scale to our staff so they can be happy and work with us as long as possible. This is the reason, we have labors who are associated with us for more than 12 years and that is a huge achievement for us. Secondly, we have a huge number of laborers that in any case if anyone leaves us then we can assign the work to another one.

2. Lack of reliable people and experienced staff – Gemstone manufacturing is a big process where everything cannot be 100% monitored that’s why you need reliable people who can be handover a stage of the process. It can be a selection of rough, cutting, polishing, etc. We have people who are with us for a long time and most of the famous are from our own family. This thing keeps things going.

3. No technology – Many manufacturers do not aware of post technology whereas, on other hand, smart manufacturers like us keep updating the technology and minimize the cost. This is the reason our prices are competitive.

4. Small customer base – Only manufacturing is not a segment, customer base is important in the same proportion. Prices will be as low as huge your customer base is. We have a big customer base all around the world and this is one of the reasons for our success. We have seen many factories who lacked in customer base and unfortunately, they have to close down.

5. Lacking in raw material sourcing – As I described above about chain so it is important to skip hands and have direct connections to survive in the market. Many manufacturers fail in this and they face the consequences.

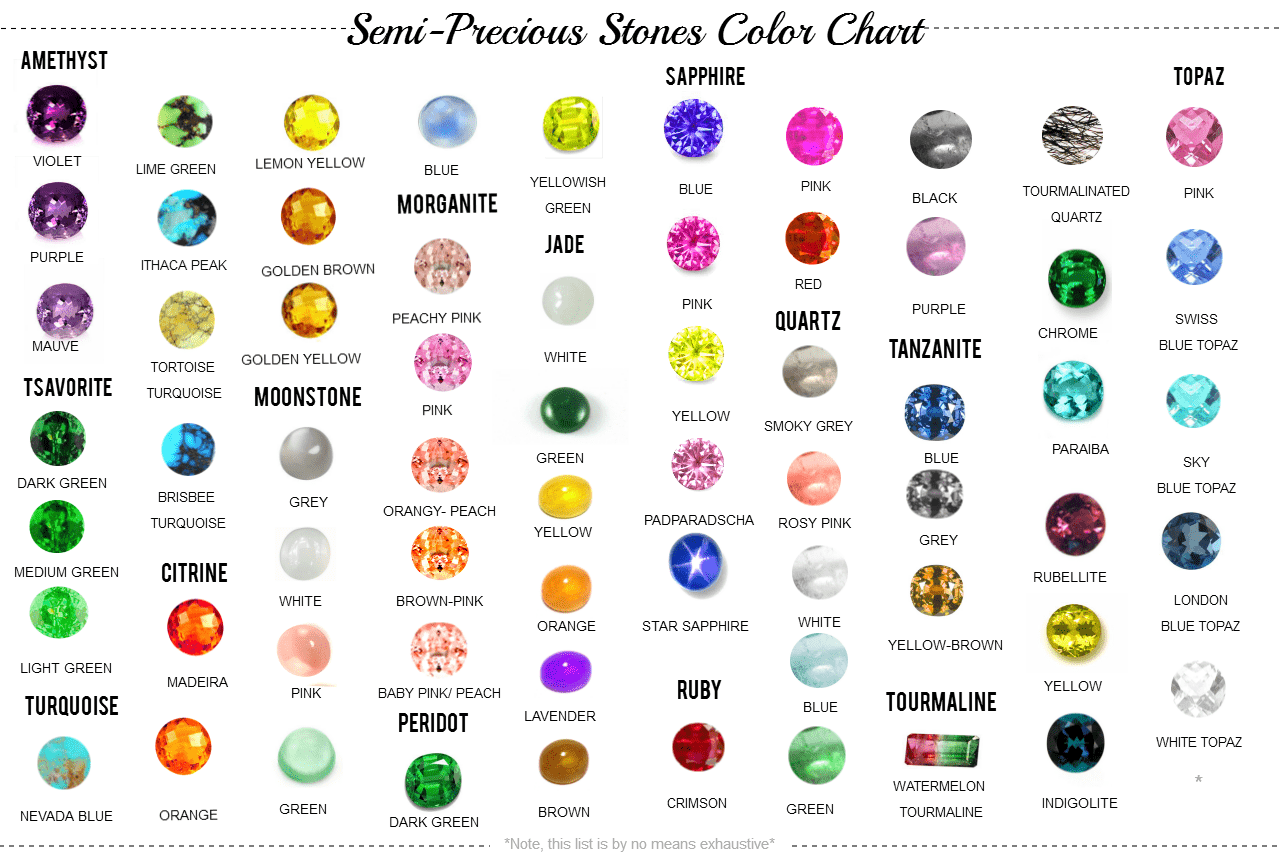

There are many more reasons like funds problem, marketing issues which are faced by companies. We have control over every aspect. Here is a semi precious gemstone color chart made by Navneet Gems:

In 2021, Mint Tourmaline have a huge demand for Tourmaline lovers. You can check here for more information at Mint Tourmaline: Freshness That Makes Cents January 2021!